Modular Nacelles for the Construction-site Assembly of Large Wind Turbines (MoMaWEA)

Project Duration: 01/2016 - 12/2016

The external dimensions of last-generation wind turbines of the multi-MW class underwent a rapid development. Manufacturers operating in this market segment have, therefore, faced with increasing challenges in terms of the concomitant logistics and transportation problems associated with the towers and rotor blades.

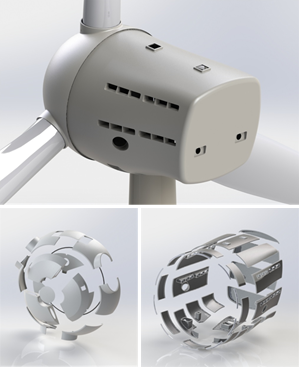

But, the outer cladding of nacelles and rotor hubs has also reached impressive proportions. Particularly in the case of gearless wind turbines, the dimensions are similar to those of major architectural works. These days they can only be transported to the construction site in their individual component parts, where they are rapidly assembled, often under the most unfavourable, adverse conditions.

The Modular Nacelles for the Construction-site Assembly of Large Wind Turbines (MoMaWEA) project is focused on the development of construction principles for modular nacelle structures. Among other things this involves the design of the external housing, issues associated with manufacturing, logistics and transportation, and rapid assembly at the construction site.

Major points of focus are the design and construction of repeated cladding elements in the interests of limiting the number of manufacturing moulds required, as well as the development of new segment connection concepts to with a view to reducing the manufacturing and assembly costs.

Eikboom GmbH of Rostock is an affiliated partner in the MoMaWEA project. For almost half a century, Eikboom has been producing plastic component groups from glass-fibre reinforced plastic (GFRP) and has achieved a high-level of relevant know-how and skill in the course of manufacturing in excess of 3000 wind turbine cladding systems.

The Project Leader Dipl.-Ing. Peter Dierken will be glad to answer any questions you may have.