Design and test of a new design concept for floating Offshore Wind Turbines (DT-NeO-WEA)

Project Duration: 04/2018 - 03/2020

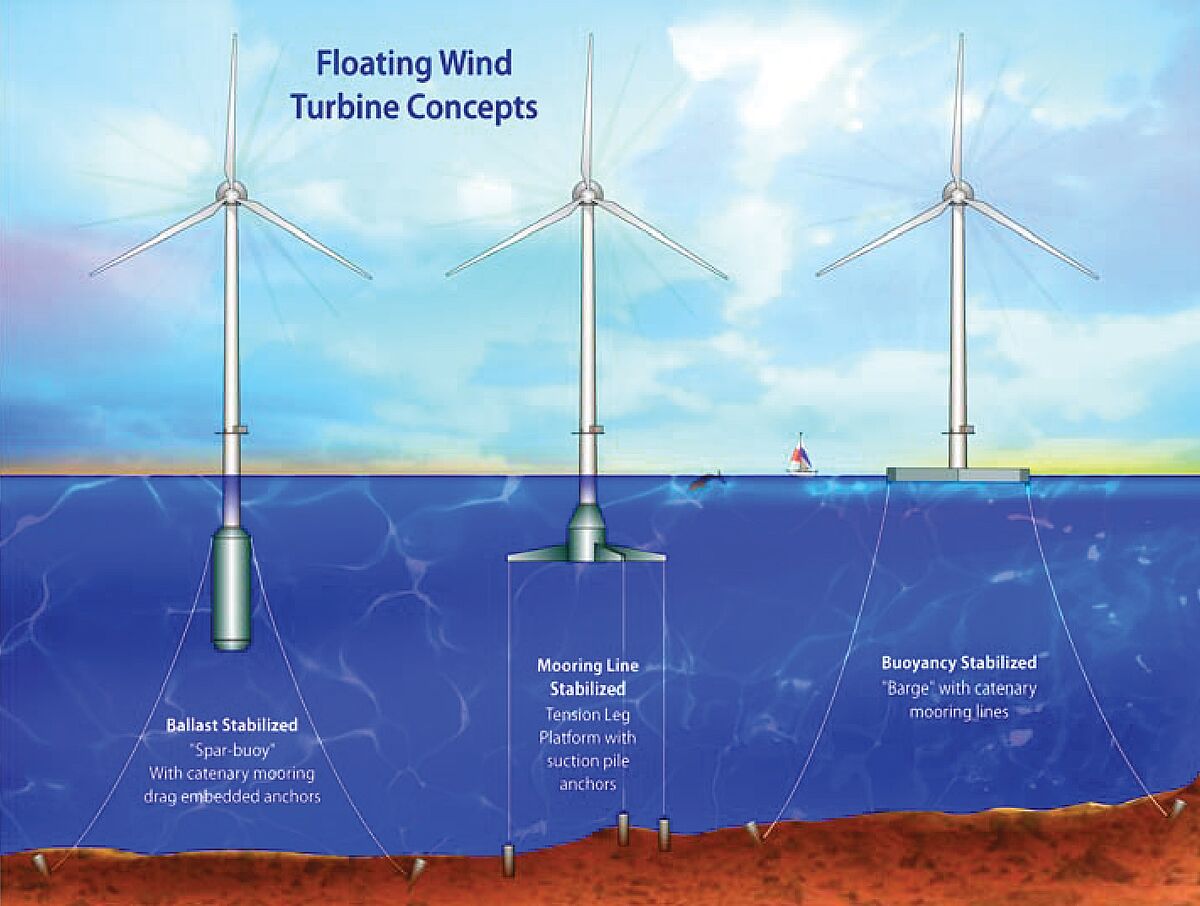

Offshore wind turbines (OWEA) play a major role in all energy transition scenarios. Previously installed facilities are located on sites with relatively low water depth (around 50m) on solid foundations. With a market share of around 85%, monopiles have been favored to date. However, the above-mentioned market share, the monopile is less suitable as a fixed foundation structure for locations with water depths greater than 100m.

If the current electricity generation costs are summed up by OWEA, it can be stated that these costs are comparatively high at around 15€ct/kWh. The latter has led to a slowdown in the expansion of offshore wind energy in recent years. However, realistic scenarios from leading energy companies (for example DONG Energy and Vattenfall) assume that cost reductions of well under 10€ct/kWh will be possible (3€ct/kWh were offered for Borkum Riffgrund). The long-term goal is to achieve offshore electricity generation costs of approx. 5€ct/kWh. In the field of floating foundation systems, there are a large number of technical solutions. Due to the specific design, which from a manufacturing point of view with a view to a highly mechanized series production is considered to be favorable, the savings buoy concept is basically the most important to attach.

Consequently, the project aims to conceptualize and develop a Spar-Buoy substructure, based on the manufacturing technologies available at EEW SPC GmbH. Thus, the foundation to be developed in terms of structure differs significantly from the previously used concepts. The same use characteristic manufacturing technologies of shipbuilding and the oil and gas industry. Furthermore, the ballast systems, which are essential for saving buoy foundations, have to be developed as well as their integration into the supporting structure. In addition to this type of active motion control by changing the position of the center of gravity, active hydrodynamic control is focussed by a drive at the foot of the spar-buoy structure as part of product development.

The Project Leader Dr.-Ing. Frank Adam will be glad to answer any questions you may have.

Project duration: 04/2018 - 06/2020

Project Staff: Daniel Walia, Hauke Hartmann, Paul Schünemann